September 16, 2021

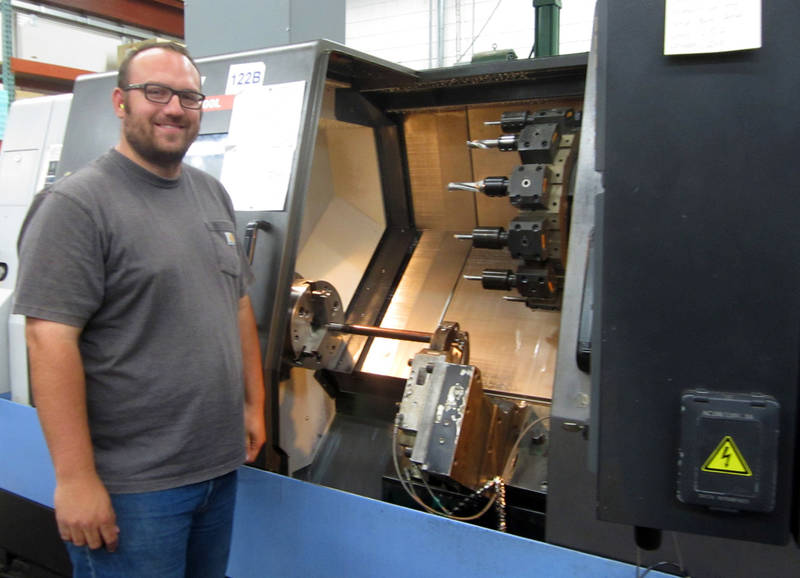

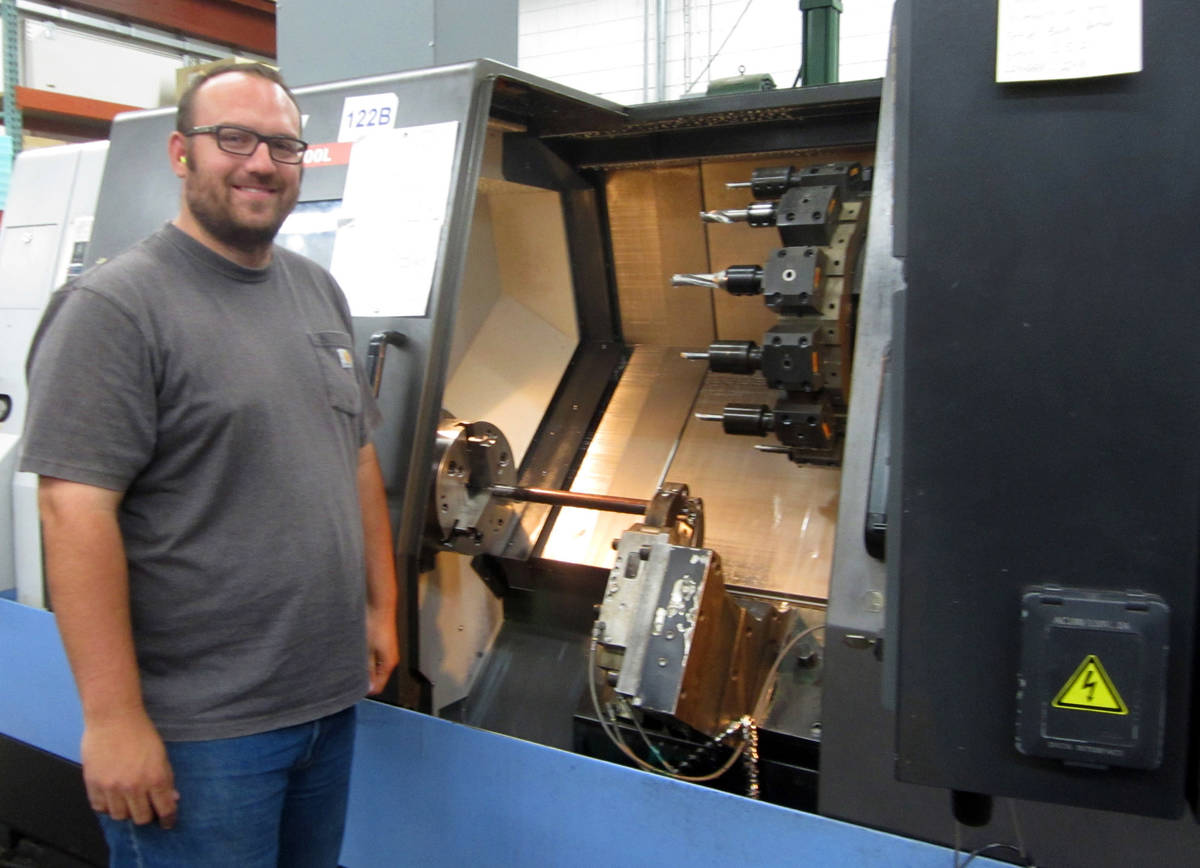

At Triumph Actuation Systems in Yakima, Washington you’ll find a manufacturing company comprised of roughly 200 total employees working on a vision to build a wide variety of components aimed at enabling the safety and prosperity of the world. With nearly 100 of those employees being machinists, representatives from Perry Tech had the opportunity to tour the facility and speak with Zack Chouinard, Supervisor, about not only the products manufactured at Triumph, but also more specifically in regards to how graduates of our 1-year Precision Machining and Manufacturing program have helped them achieve their mission of partnering with customers to triumph over their hardest aerospace, defense and industrial challenges to deliver value to their stakeholders.

Graduates of Perry Tech are trained with the goal of being able to provide an employer with entry level machining and manufacturing skills capable of performing the foundational elements of the trade. According to Chouinard, “At Triumph, with thousands of different parts being manufactured, an entry-level machinist has the opportunity to work their way up through the ranks.” The Triumph Actuation Yakima location features 125 various machining centers which range from manual machines to 9-axis mill turns. When asked what makes Perry Tech grads so attractive Chouinard said, “The curriculum at Perry Tech starts these machinists off on manual machines and then exposes them to CNC controlled equipment. That gives them a well-rounded foundation when they enter the workforce. So, when they come through our doors with that basic knowledge of machining principals, we have something to build upon while keeping production going.”

Of the 100 machinists employed at the Yakima location alone, roughly 80 percent are Perry Tech graduates. “The new machinists generally start with tasks such as manual lathe, and honing work. Later they move to roughing lathes and/or deep-hole gun drills and work their way up from there to more complex equipment.,” explained Chouinard when discussing a typical machinist career path at Triumph. Chouinard continued, “Many of the manufacturing engineers and CNC programmers and supervisors we have here started on the machine shop floor first, so there is room to grow. We even developed specialized training through Perry Tech as part of our continuous learning model that makes our employees more valuable to us and themselves.” While the average tenure for machinists is approximately 16 years on the job, Chouinard states, “If a machinist is willing to work hard and learn, even after 15 or 20 years, there will always be an opportunity to learn something new and professionally grow.”

To learn more about the Precision Machining & Manufacturing program, schedule a program tour. For info on hiring Perry Tech grads, contact us at 509.453.0374 or [email protected].

PTI Alumni Derek Dowdy

PTI Alumni Don Dowdy

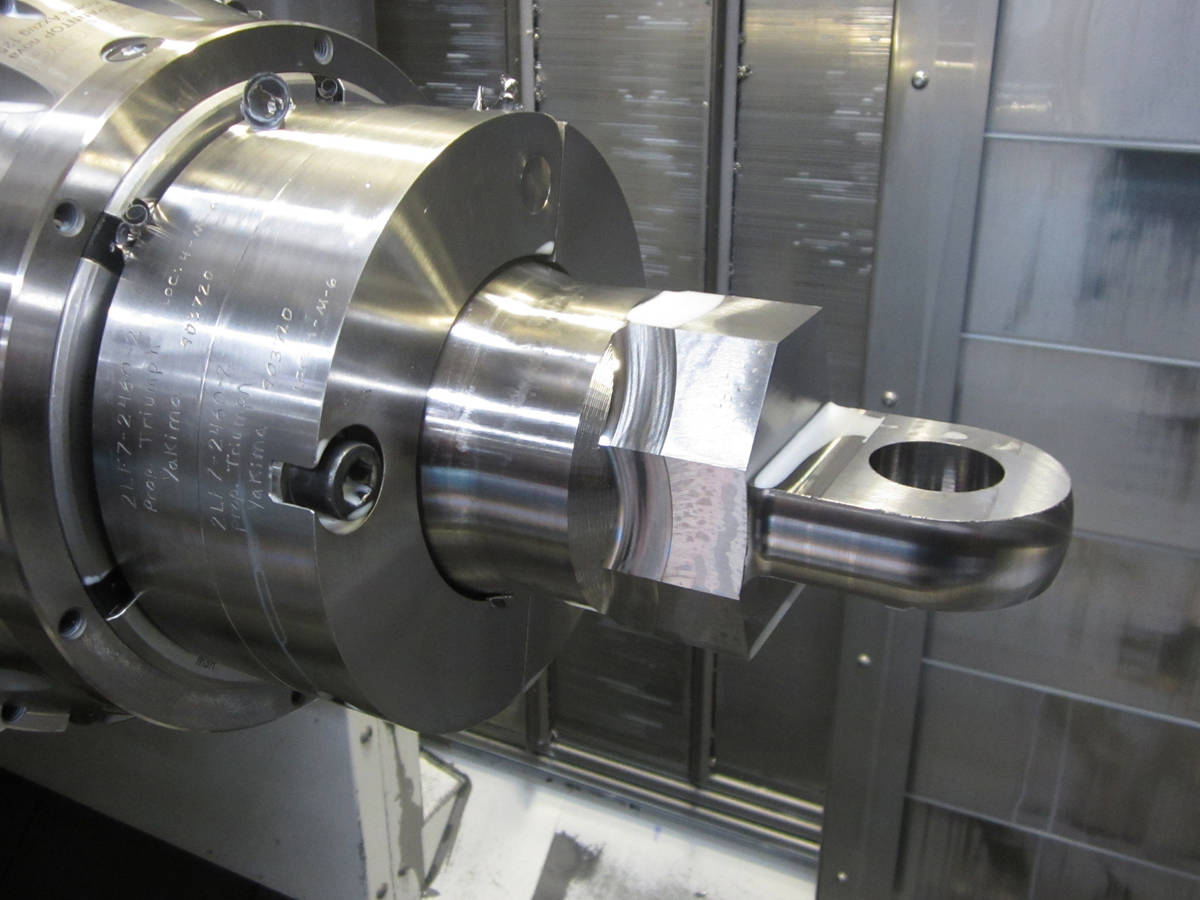

CNC mill-turn machine producing a titanium part for a Boeing 777 aircraft